Our References

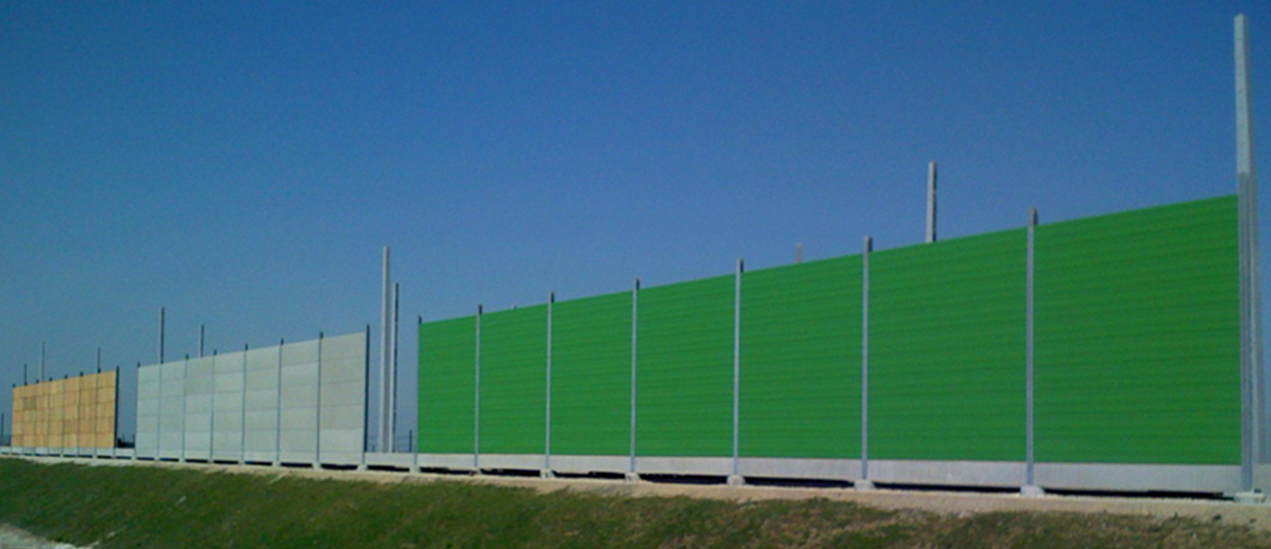

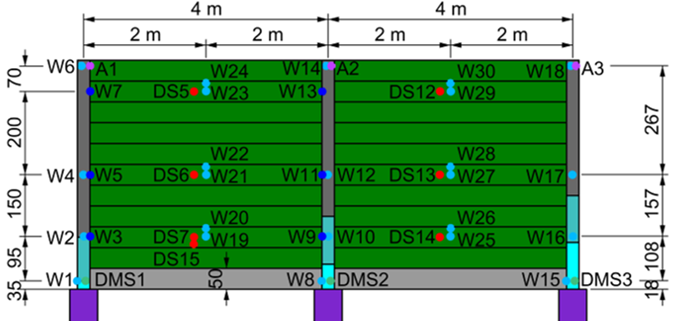

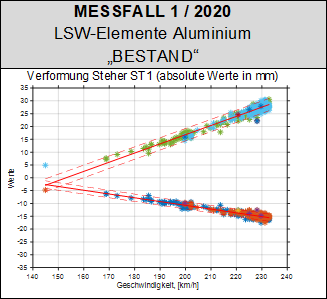

2022 – ongoing: Impact model for determining the remaining service life of noise barriers constructions on the railway

In this project, aerodynamic load approaches are determined for noise barriers on railway lines and made available as a basis for fatigue strength tests of existing noise barriers. In addition to a fundamental study of the aerodynamic loads that occur in the form of a sinusoidal function when trains pass, extensive dynamic measurements of the effects and reactions are also carried out on representative railway lines in Germany. Absolute pressure, acceleration and strain sensors will be used for the measurements. In addition, a "mobile train identification system" developed by REVOTEC will also be installed and this will enable the number of train journeys per day/month/year, the types of trains and their current train speed to be determined. The aim of the project is to develop reality-adapted aerodynamic load approaches that can also be used, among other things, for residual service life calculations of existing noise barriers.

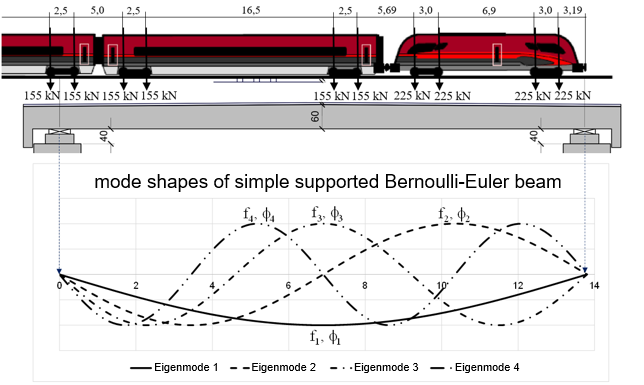

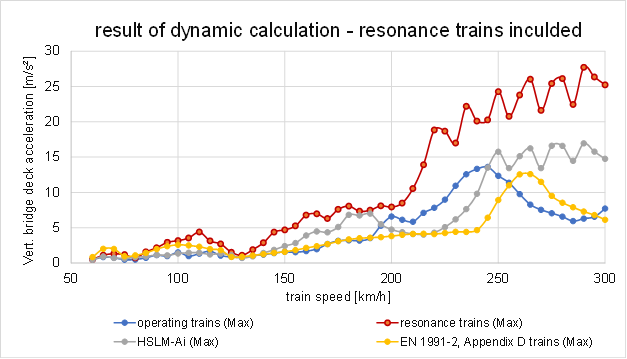

2020 – 2023: FRA Project – New dynamic load model for railway bridges

In this project commissioned by the Federal Railway Authority (FRA), new load models for the dynamic calculation of train crossings of railway bridges were developed together with an international consortium (TU Darmstadt, KU Leuven, Austrian Institute of Technology and REVOTEC). The reason for this development project, which was endowed with 1 million euros, was the knowledge that the current high-speed load models (HSLM-A and HSLM-B) defined in Eurocode EN 1991-2 no longer cover in any way the operational trains (passenger and goods trains) actually running on the European railway network with regard to the vibration response behaviour of bridges during train crossings. In the last 10 years, it has been found very often that new operational trains such as the Railjet in Austria or the ICE 4 in Germany cause an acceleration and internal force response that is not covered by the standardised HSLM trains. Therefore, completely new passenger and goods train load models for the dynamic calculation of railway bridges were developed in the project.

2020 – ongoing: Development of fatigue load model for railway bridges

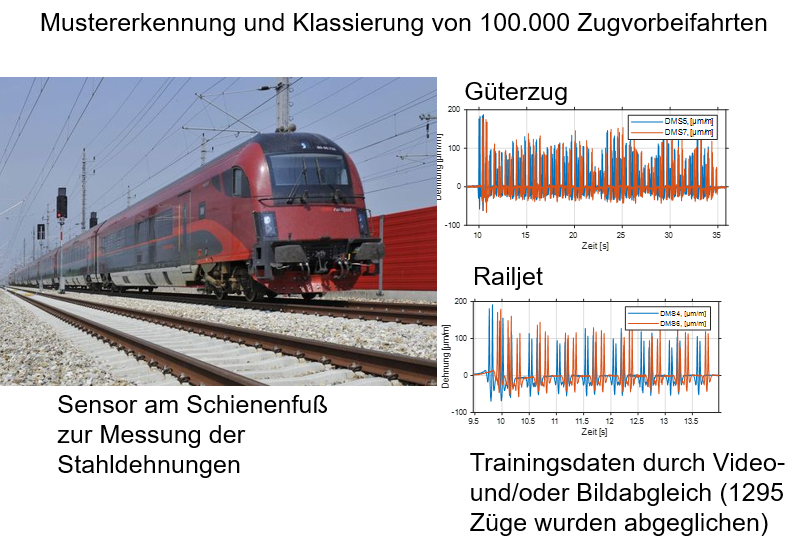

In this research project funded by the Federal Ministry of Digital Affairs and Transport, the aim is to develop a reality-adapted fatigue load model for railway bridges made of steel. The project is endowed with 1.5 million euros and REVOTEC is conducting research together with the project partners TU Darmstadt, DB Campus 4.0 and the Austrian Institute of Technology on the development of the new fatigue load model for railway bridges. The acronym DEEB-INFRA stands, translated, for Data-based Extrapolation Model for the Determination of Real Operational Load Trains for (Residual) Lifetime Analyses of Railway INFRA Structural Systems, and this long title very accurately describes the goal of the research project. In addition to the theoretical development work, measurement data from axle load measuring points in Austria & Germany are also analysed to determine the actual train numbers that occur and in particular the actual axle loads. Historical operating data, which is important for the development of the fatigue load model, is also made available by DB (German Railway) in the project.

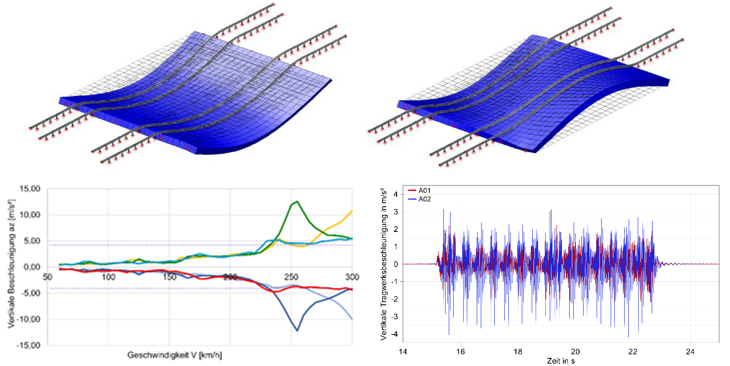

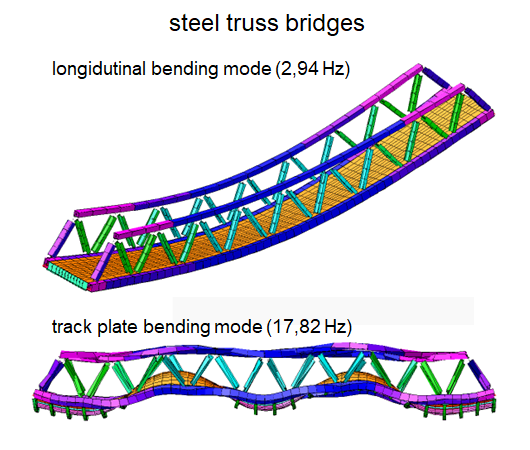

2020 – ongoing: Dynamic calculations and measurements of the train crossing of railway bridges in accordance with the regulations RW 08.01.04 und RW 08.01.05

Since its foundation in 2014, REVOTEC has been performing dynamic calculations and measurements of train crossings on railway bridges. For the dynamic calculations, spatial FE models of the railway bridge to be investigated (new or existing) are created, and the trains to be investigated according to the ÖBB regulations RW 08.01.04 are assumed as moving loads in the speed range considered. The evaluation of the calculation results is also carried out according to RW 08.01.04.

If defined limit values are exceeded e.g., the vertical acceleration of the supporting structure, REVOTEC also carries out continuous dynamic measurements to determine the actual system properties (natural frequencies, associated vibration modes and Lehr's damping coefficients) in accordance with the ÖBB regulations RW 08.01.05. In addition to the impulse excitation with falling weight and/or train passage itself, the high-precision force-excited vibration excitation method can also be carried out using electrodynamic shakers.

2022 – Structural Health Monitoring Hamburg

The focus of the infrastructure monitoring for this project is on two road bridges in Hamburg. The work and implementation is being carried out in a consortium with ISEAtec from Friedrichshafen. The project is very close to research, as the client (Helmut Schmidt University) is evaluating the sensor systems available and applied on the market over a period of 2 years. The consortium is responsible for the complete planning, ordering, logistical implementation, installation, commissioning, operation and data management. Physical parameters such as accelerations, inclinations, structural strains, bearing paths, coupling joint openings, component temperatures, weather data and axle loads are measured.

The two bridges are a prestressed frame bridge with a span of approx. 50 m with 149 measuring points and a plate girder bridge over 7 spans consisting of 2 partial structures, each with a total length of 245 m and 275 measuring points. The continuous and automated provision of data to the client takes place over a period of at least 2 years.

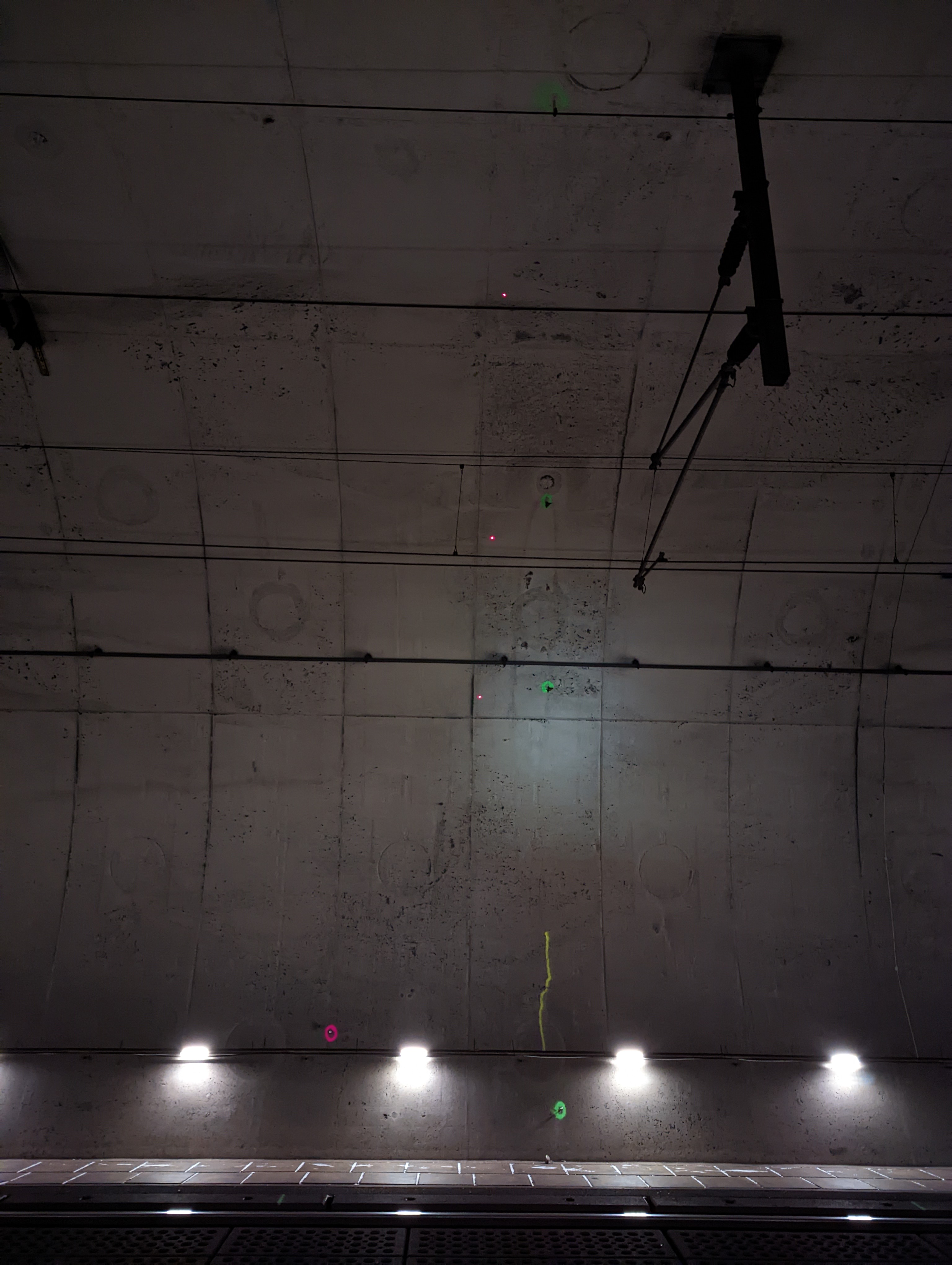

2022 – Crack Monitoring Unterwaldtunnel

At the western portal of the double-track Unterwald Tunnel, crack widths are monitored at 48 measuring points to determine whether slope movements have already consolidated in this tunnel section. Furthermore, the tunnel geometry and the temperatures of the tunnel shell are monitored at 5 measuring cross-sections using laser distance sensors. This monitoring serves, on the one hand, for operational safety in order to detect changes in the tunnel lining at an early stage and, on the other hand, to determine the geological mechanisms in conjunction with other measurement methods.

The monitoring system automatically transmits the data of all measuring points to the REVOTEC web portal for evaluation and visualisation of the data. The customer can access the data in real time at any time or make correlations with other data sets. The failure of sensors or the exceeding of warning or alarm criteria is also monitored by the web portal.

2023 – Operational Monitoring Mürz Bridge near Kapfenberg

As part of the COMET project "Rail4Futere", commissioned by the Institute for Steel Construction at TU-Graz, an operational monitoring is being carried out on the Mürz Bridge near Kapfenberg. At the two-span steel structure with an open track, steel strains during train passage, the bearing movements as a result of temperature as well as the air and component temperatures are measured at 46 measuring points. Furthermore, the traffic loads in the form of vehicle type and axle loads are recorded by means of sensors on the rail and the REVOTEC software TrainClass. Over a period of at least 2 months, all train crossings are automatically recorded and classified according to vehicle type (Cityjet, Railjet, Eurocity, goods trains, etc.). Thus, in post-processing, the operating loads are recorded without gaps over the measurement period and the vibration cycles are evaluated for each strain measurement point by means of Rainflow analysis. The data is used in the research project for model validation as well as for comparing actual operating loads with normative fatigue loads.

2021 - position monitoring of the river piers at the Drau Bridge near Stein

Static monitoring is being carried out on two river piers at the five-span composite structure over the Drau near Stein in Carinthia. In the course of geodetic surveys, it was found that irregular position changes occur at 2 pier heads. In order to obtain more informative data on the behaviour of the piers, REVOTEC zt gmbh implemented a monitoring system to determine the position of the piers. The position in the longitudinal direction is continuously monitored by means of laser distance sensors, the lateral movements are monitored by means of inclination sensors.

The data is continuously transmitted to the REVOTEC web portal and clear movements in the sense of an annual hydrograph (from the temperature expansions of the supporting structure) have been detected in the measurement period to date. In the meantime, the client has secured one pier to the abutment by means of guy wires; additional force sensors were installed on the guy wires and integrated into the monitoring system. The tensioning of the guy ropes was also precisely controlled and checked by the position monitoring.

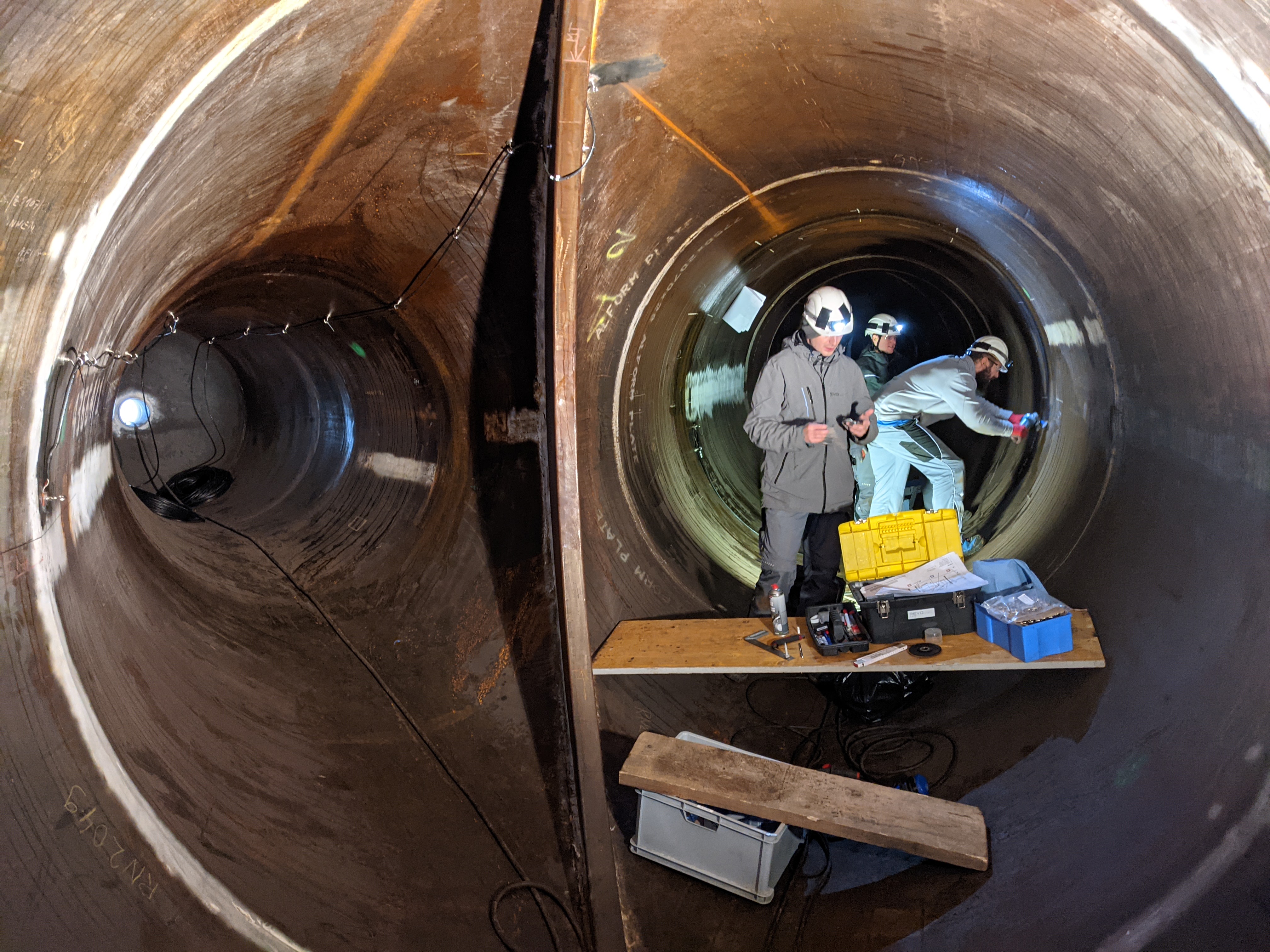

2021 - Pressure test on the Rodund I distribution pipeline

In the course of the renovation and expansion of the Rodund I power plant, the distribution pipeline (DP) to the powerhouse was renewed. The DP extends from the foot of the headrace tunnel over a length of approx. 80 m and changes the internal diameter from 4000 mm to 1200 mm, with the cross-section changes taking place at each branch. For the DP, a pressure test was carried out for quality assurance purposes and strain measurements were carried out on the inside and outside in the area of stub 3 and 5. For the inside, proprietary pressure-tight cable passages and installation techniques were used.

The pressure test was successfully carried out with static pressure levels between 10 and 60 bar, without any pressure drop or local expansion drop being detected. After the pressure test, the entire measurement technology remained with the customer, as the installation was designed for permanent operation. The background to this is the continued operation of the measuring points (except for those inside) in regular operation in order to evaluate the effect of the concrete support body on the pipe forces.

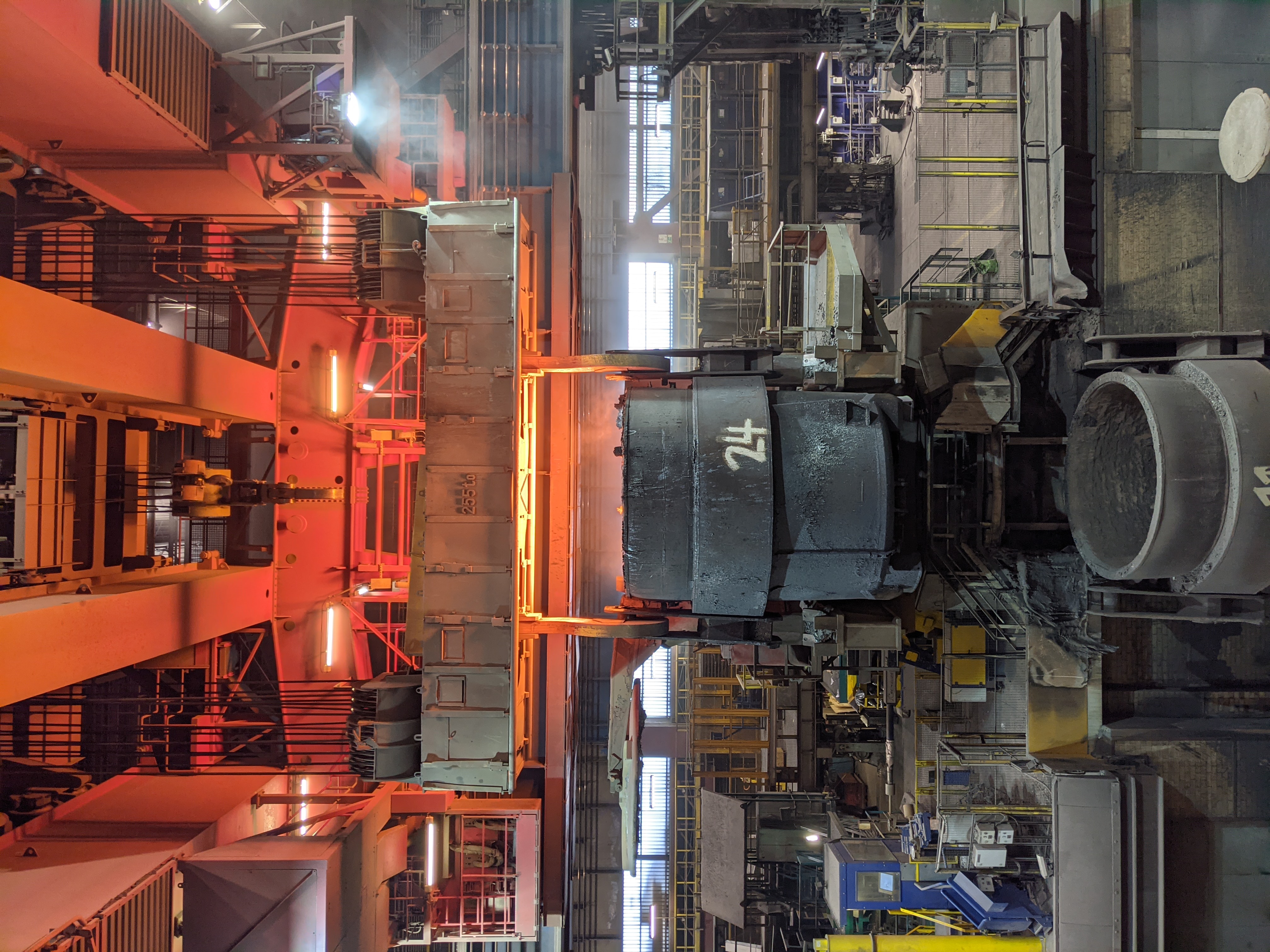

2021 - Strain measurement on an operating crane runway at voestalpine Stahl GmbH in Linz

For the new planning of the crane runway girders in the LD3 blast furnace operation, the operating collectives were recorded at 40 measuring points on one of the steel girders to be replaced. One girder is designed as a single-span girder with a span of 25 m between the hall supports and measures a height of approx. 3000 mm. The total length of the hall is 600 m and the crane system in the hall is used to transport the "ladles" (approx. 600 t) for the liquid steel for further processing. The challenge for the measuring system was to make it particularly robust and heat-resistant, as temporary radiation temperatures of up to 100 °C were possible when the ladles approached the measuring points. Therefore, the cabling and the sensors had to be designed for these temperatures.

The measurements were successfully carried out in order to record the strain changes during operation when the beam of the two cranes with the filled ladles passed over. Using the recorded data, the client can use the annual load cycles from the cranes' log data for the fatigue calculation.

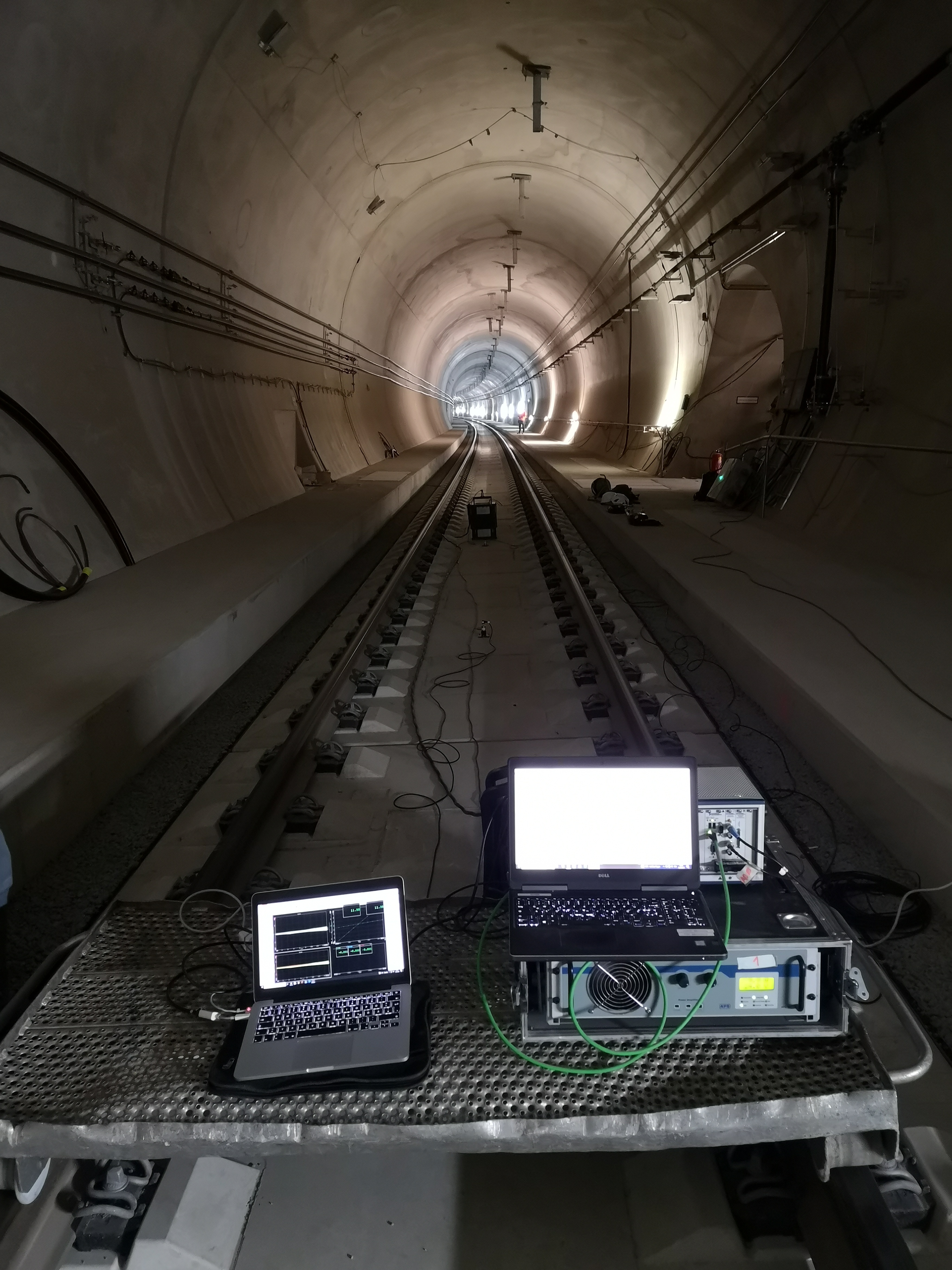

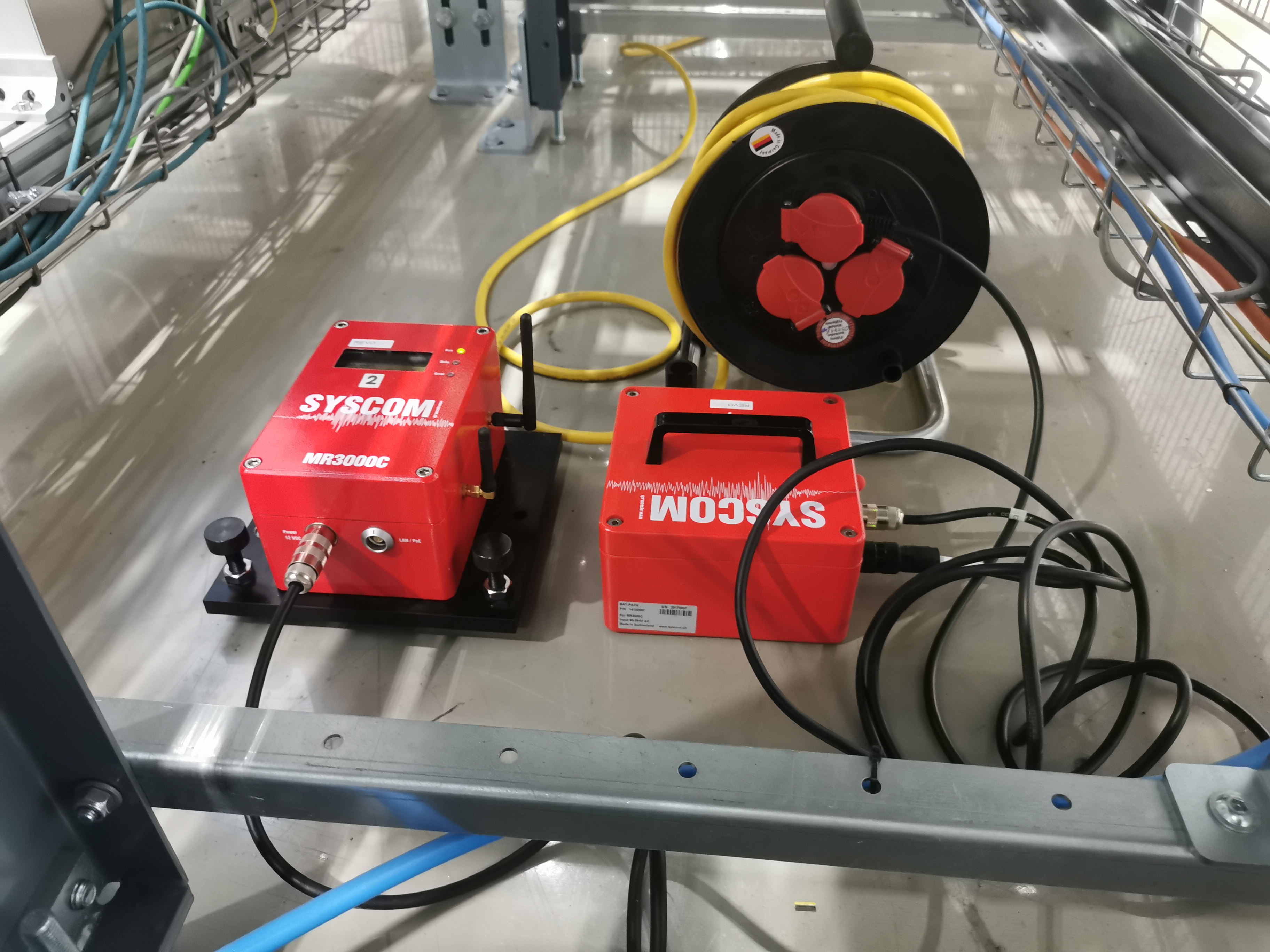

2023 - Acceptance measurements of the mass-spring systems in the Ganitzaltunnel on the Koralm Railway

In the course of the new construction of the Koralm railway, mass-spring systems are required as part of the superstructure in the area of the tunnel structures to reduce the vibration immissions caused by train traffic in residential areas. These mass-spring systems are designed in the course of the detailed planning for the superstructure according to the preliminary investigations and are tuned to 15 - 20 Hz by the elastic bearing, the concrete mass and the vehicle properties. Acceptance measurements were carried out to check the required insulation level after execution. REVOTC zt gmbh owns electrodynamic shakers to perform force-excited vibration measurements. These shakers are placed on the mass-spring systems by two persons and frequency sweeps are performed to record the responses of the mass-spring systems using accelerometers.

The results are characteristic frequency-amplitude responses, and the resonant frequency and Lehr’s damping of the mass-spring systems are determined. For the mass-spring systems in the two-tube Granitzaltunnel, very good results were achieved structurally with deviations of the planned tuning frequency (without tensile mass) of less than 5 %. This means that the required damping dimension can be met very well.

2023: Vibration and secondary airborne noise Traisental railway

In this project, the vibrations and secondary airborne noise occurring due to railway traffic were determined and assessed in accordance with ÖNORM S 9012 for the protection of people in buildings. For the determination of the immission quantities, vibration measurements were carried out at the point of origin (emission), at the point of transmission (transmission) and at the point of impact of the building (immission). The forecast calculation was carried out using transmission frequency spectra.

In this project, it was thus assessed whether, after project implementation in the operational phase of the Traisental railway, people in buildings adjacent to the railway line, in particular in their flats, could be affected by vibrations and/or secondary noise.

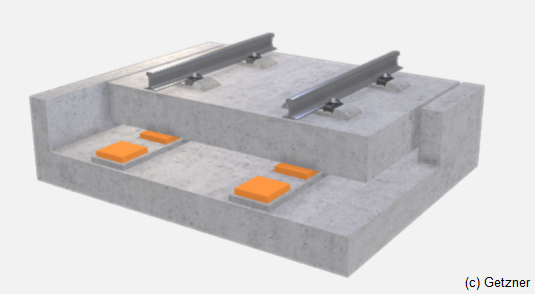

2023: Dimensioning mass-spring system for Magdeburg tram line

In this project, a mass-spring system was implemented for a tram line to reduce the vibration input into the subsoil. The mass-spring system consists of a reinforced concrete slab, which was elastically supported over its entire surface. The surface bearing was made of a sylomer material, the stiffness of which was optimally adjusted in relation to the target tuning frequency and limitation of the subsidence due to the rail vehicle. With the design of the mass-spring system, a significant reduction of the railway-induced vibration immissions is already achieved directly at the track i.e., at the vibration source, and thus an effective protection of residents of the adjacent buildings from vibrations and secondary airborne noise is achieved.

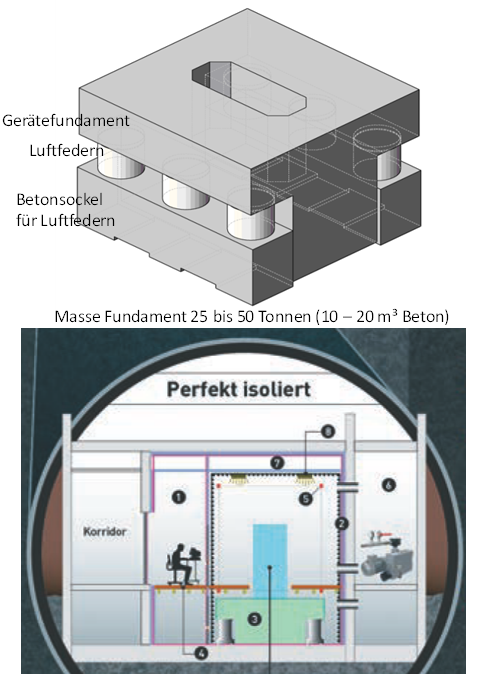

2022 – 2023: Equipment foundations for highly sensitive scanning electron microscopes of the TU Vienna

In this project, the decoupled equipment foundations for scanning electron microscopes required to achieve the greatest possible freedom from vibration were planned for a new research laboratory of the Vienna University of Technology in Stadionallee in 1020 Vienna and their constructional implementation was accompanied by measurement technology. The equipment foundations consist of a "heavy" rigid concrete block with a dead weight of up to 60 tonnes and a bearing on active air springs. Due to the active air spring support, tuning frequencies of the equipment foundations of < 1.2 Hz are achieved and the requirements for the interference-free operation of the scanning electron microscopes (VC curves) are met. Vibration measurements of the immissions at the construction site formed the basis for the planning of the equipment foundations and their air spring support. The vibration measurements were subsequently carried out during construction and compliance with the VC curves was confirmed.

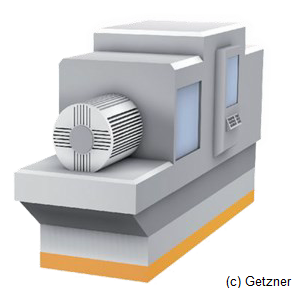

2022: Elastic unit mounting to reduce the vibrations of a storey ceiling

In this project, the vibrations of a floor slab resulting from the operation of a pulse-generating device were measured and assessed with regard to possible fatigue damage to the building structure. The dynamic deformations were derived from the ceiling vibration velocities measured during operation of the device and the damage to the reinforcing steel was calculated from this. In order to reduce the impulsive input of the vibration energy into the floor slab, an elastic unit support was planned and structurally implemented using a sylomer material with an areal design. After implementation of the elastic equipment support, the vibrations of the floor slab were measured again, and the reduction and positive effect of the elastic support was confirmed.